How Portable Electronic Vents help solve the dual design challenges of preserving acoustic sound quality and device reliability.

The challenge of designing electronic devices that stay protected from dust, liquids and pressure becomes increasingly difficult when acoustics are introduced.

The challenge of designing electronic devices that stay protected from dust, liquids and pressure becomes increasingly difficult when acoustics are introduced.

To enable sufficient sound transmission, devices require apertures. But these apertures that let the sound out also allow dust and liquids to enter the device and create performance and reliability issues. Creating clear crisp sound while protecting device reliability requires careful design of the cavities in front of and behind all transducers.

Evaluating Design Options for the Front Cavity

Open apertures provide unimpeded sound, but provide no protection from dust, liquids or immersion — hazards that nearly all portable electronics encounter. Designs with open apertures are highly susceptible to component failures, decreased device life and consumer perceptions of poor quality.

Open apertures provide unimpeded sound, but provide no protection from dust, liquids or immersion — hazards that nearly all portable electronics encounter. Designs with open apertures are highly susceptible to component failures, decreased device life and consumer perceptions of poor quality.

Waterproof transducers that seal the front cavity from the device prevent water and dust contamination from reaching components. But, waterproof transducers still allow water and particulates onto and around the transducer surface, which degrades acoustic performance over time. Additionally, waterproof transducers often impose an “acoustic penalty” by providing lower overall acoustic quality and requiring increased drive power levels to operate the transducer.

Non-porous covers such as urethane, silicone or PEEK can be used to cover apertures when immersion protection is needed. They can allow satisfactory sound transmission while protecting the transducer from dust and liquid submersion. However, these materials do not breathe. When pressure in the front cavity builds (due to temperature or altitude changes), the pressure on the compliant surfaces of the transducer increases. This pressure creates transducer bias that can significantly degrade sound quality and transducer performance.

Acoustic Vents for immersion applications offer new solutions to the challenges of designing front cavities. The ePTFE membrane in Caron’s immersion vents protects the transducer and the device from dust and liquid immersion up to IP68. Our highly breathable ePTFE membrane rapidly equalizes pressure in the front cavity, continuously providing exceptional acoustic performance in all designed conditions.

Additional Considerations for Dust and Splash Protection

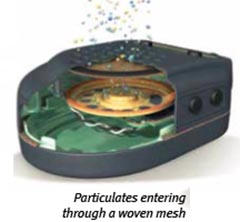

Woven mesh covers are a partial solution, in that they can protect an aperture from liquid splash, spray or rain. However, these products consist of a single-layer grid and spacing pattern with a defined hole size. So any dust particles smaller than the defined hole size will pass through the screen and deposit on the transducer, or they will propagate through the device, potentially causing catastrophic device failure

Woven mesh covers are a partial solution, in that they can protect an aperture from liquid splash, spray or rain. However, these products consist of a single-layer grid and spacing pattern with a defined hole size. So any dust particles smaller than the defined hole size will pass through the screen and deposit on the transducer, or they will propagate through the device, potentially causing catastrophic device failure

Acoustic Vents for dust and splash applications provide added protection because of their non-woven structure. While they reliably repel liquid splash, spray or rain exposure, they also offer greater protection from small particles. Caron’s expertly engineered non-woven materials provide a tortuous path that more effectively traps smaller particulates. This added protection reduces quality issues and improves device functionality.

Evaluating Design Considerations for the Back Cavity

Sealed housings protect electronic devices by providing a barrier against water or dust. But as electronic devices operate they generate heat, causing internal temperatures to increase and pressure to build inside the housing. Internal pressure can also change rapidly if the device is exposed to sudden changes in environmental temperatures or altitudes. These internal pressure changes put significant stress on the housing seals. Over time this leads to failed seals, which then allow water and contaminants to enter the device.

When dealing with acoustic transducers, there is an additional problem with sealed back cavities: pressure on the compliant surfaces of the transducer can create transducer bias, which can greatly degrade sound quality and transducer performance.

Caron Pressure Vents are specifically engineered for back cavities. Their breathable construction effectively equalizes pressure while providing reliable protection from liquid submersion and dust contamination. Our product portfolio includes a range of materials and structures that meet the most challenging environmental demands and application needs

Qingdao Caron Technology Co.,Ltd

Tel:+86 532 55566617 55566618 Sales Hotline:13395320098 Fax:+86 532 55566616

Add:R&D Center of Shengwen,Shuyun East Road, Xiazhuang Street, Chengyang District, Qingdao, China. E-mail:service@carontech.com.cn