PROTECTIVE VENTS

背胶型防水透气产品

Caron Protective Vents are designed to protect enclosures and devices from particles, water, oils, and other liquids without negatively affecting their operation. They are comprised of a filtration material and a pressure-sensitive adhesive ring for securing the vent to the device.

凯荣背胶型防水透气产品用于保护外壳和设备免受颗粒、水、油和其他液体的影响,同时不会对其操作产生影响。 它们由透气膜和用于将透气膜固定到装置的压敏胶环组成

FEATURES & BENEFITS(主要特点和优点)

• High efficiency particulate removal

高效去除微粒

能够讓气体流过和进行压力均衡

• Eliminates the need for costly hermetic sealing

高性价比,省去了昂贵的气密密封的需要

• Repels water, oils, and other liquids

防水、油和其它液体

• Oil ratings from 1 to 8

防油的等级分为1至8

• IP ratings from IP44 to IP67/IP68

IP 的防护等级可从IP44 到IP67/IP68

• Easy application and device integration

易于应用和设备集成

• Non-adhesive protective vents also available for welding to your device

不带背胶的透气膜也可被用于焊接到设备上

• Standard and custom sizes and shapes are available

标准化和自定义尺寸、形状都可供选择

• Caron's Vents provide protection with excellent sound transmission

凯荣的防水透声膜,提供产品保护,并兼具出色的声音传输性

STANDARD MATERIALS AVAILABLE (标准材料可选择)

• The many options include Caron's proprietary white or black ePTFE membrane,woven, nonwoven,

and extruded materials such as nylon, polyester, Polypropylene, and polyester/polyethylene.

许多选项包括凯荣的白色或黑色ePTFE膜,纺布,无纺布和挤出材料,如尼龙,聚酯,聚丙烯和聚酯/聚乙烯

• Hydrophobic, oleophobic, and acoustic materials are available

可提供疏水,疏油和声学材料

• Thickness: < 0.3mm (< 0.012")

厚度:<0.3mm(<0.012“)

• Continuous Operating Temperature Range: -40° to 149°C (-40° to 300°F)

连续工作温度范围:-40°至149°C(-40°至300°F)

• Minimum efficiency of 99.97% on 0.1 µm particles

在0.1μm颗粒上的最小过滤效率为99.97%

• Material data sheets available upon request

可根据要求提供材料物性表

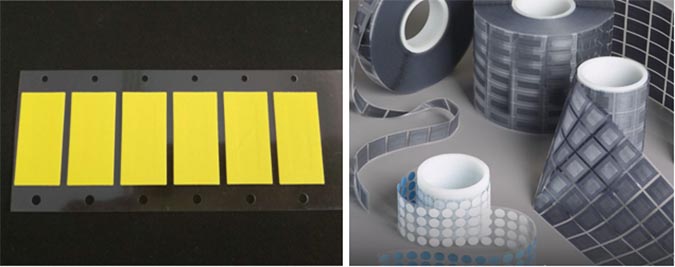

PACKAGING(包装方式)

• Manufactured, inspected and packaged in clean room environment

在洁净室环境中操作,检查和包装

• Supplied on continuous release liner: 2000 - 5000 parts per polyethylene cores

供应连续的离型纸:每一个聚乙烯卷芯带2000 - 5000个透气膜

• Roll sealed in cleanroom bag unless otherwise specified

除非另有规定,将卷膜封入洁净袋子里

PRODUCT OFFERINGS(产品展示)

|

模式 MODEL |

产品型号 PART NUMBER |

透气量 AIRFLOW (L/H/CM²@70mbar) |

耐水压 WATER ENTRY PRESSURE(psi@30sec) |

疏油 OLEOPHOBIC |

颜色 COLOR |

厚度 THICKNESS |

|

|

标准透气量Standard |

CRBV1657 |

>20 |

>14.5 |

YES |

黄色 yellow |

0.13mm |

|

|

高透气量 High Airflow |

CRP1950 |

257 |

>10 |

YES |

白色 white |

0.19mm |

|

|

标准透气量Standard |

CRP1910 |

35 |

>14.5 |

YES |

白色 white |

0.14mm |

|

|

标准透气量Standard |

CRP1943 |

35 |

>14.5 |

YES |

黑色 black |

0.20mm |

HANDLING INSTRUCTIONS(操作说明)

• Wear gloves or use rounded tweezers when handling the vents

操作透气膜时戴手套或使用圆形镊子

• Mounting surfaces should be clean and free of oils, particles, and other contaminants

安装表面应清洁,无油污、颗粒和其他污染物

• Vents should be mounted on flat, vertical surfaces where liquids or other contaminants will not pool

透气膜应安装在平坦,垂直的表面,液体或其他污染物不会聚集的地方

• Follow dispenser instructions when using an automated vent dispenser

使用自动离型分配器时,请遵循分配器说明

• For manual vent dispensing, roll the liner under the vent until the vent extends beyond the liner and

becomes easily accessible

对于手动取下透气膜,在透气膜下方卷动离型纸,直到透气膜与离型膜分离

• Do not pry the vent from the liner or fold the vent, as this could damage the vent

不要从离型纸上撬出透气膜或折叠透气膜,因为可能会损坏透气膜

ASSEMBLY INSTRUCTIONS(装配说明)

• Accurate placement of the vents can be improved by using markings, a recessed area, or a target area in which the vent is centered over the vent hole in the device or housing

可以通过使用标记,凹陷区域或目标区域来改善透气膜在装置或壳体的精确放置

• Apply light finger pressure to the adhesive ring to seal the vent to the device or housing

对粘胶环施加轻微的手指压力,以将透气膜密封到设备或外壳上

• Do not attempt to reposition the vent after installation. This can cause damage to the vents

安装后不要尝试重新放置透气膜,这可能会损坏透气膜

• Allow at least 24 hours dwell time before using or testing the vent

在使用或测试透气膜之前至少要放置24小时

Qingdao Caron Technology Co.,Ltd

Tel:+86 532 55566617 55566618 Sales Hotline:+86 13395320098 Fax:+86 532 55566616

Add:R&D Center of Shengwen,Shuyun East Road, Xiazhuang Street, Chengyang District, Qingdao, China.

E-mail:service@carontech.com.cn